Automotive & Auto Parts

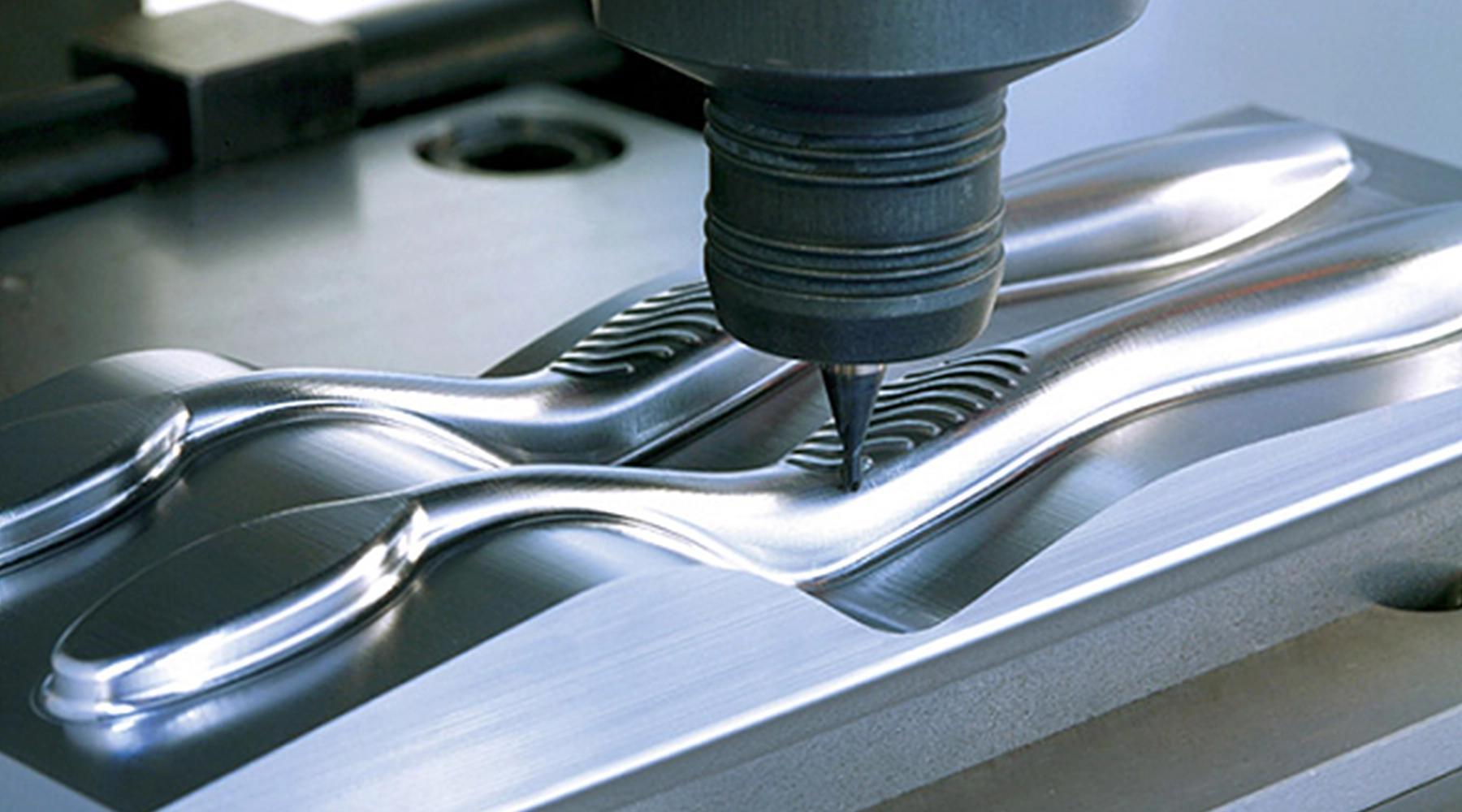

Advanced manufacturing solutions for automotive assembly lines, engine components, and precision automotive parts production.

Industries

Over 119 years of experience delivering tailored solutions for Argentina's most demanding industrial sectors.

Advanced manufacturing solutions for automotive assembly lines, engine components, and precision automotive parts production.

Heavy-duty machining centers and robust equipment designed for large-scale industrial manufacturing and heavy machinery production.

Specialized tooling and mold-making solutions with high-precision machining for injection molding and stamping dies.

Robust equipment and specialized machining solutions for oil & gas infrastructure, pipelines, and energy sector components.

Ultra-precision machining and quality control systems for aerospace components requiring the highest standards of accuracy.

Comprehensive metalworking solutions including CNC machining, turning centers, and automation for metal fabrication.

Heavy-duty equipment and maintenance solutions designed for the demanding conditions of mining operations and mineral processing.

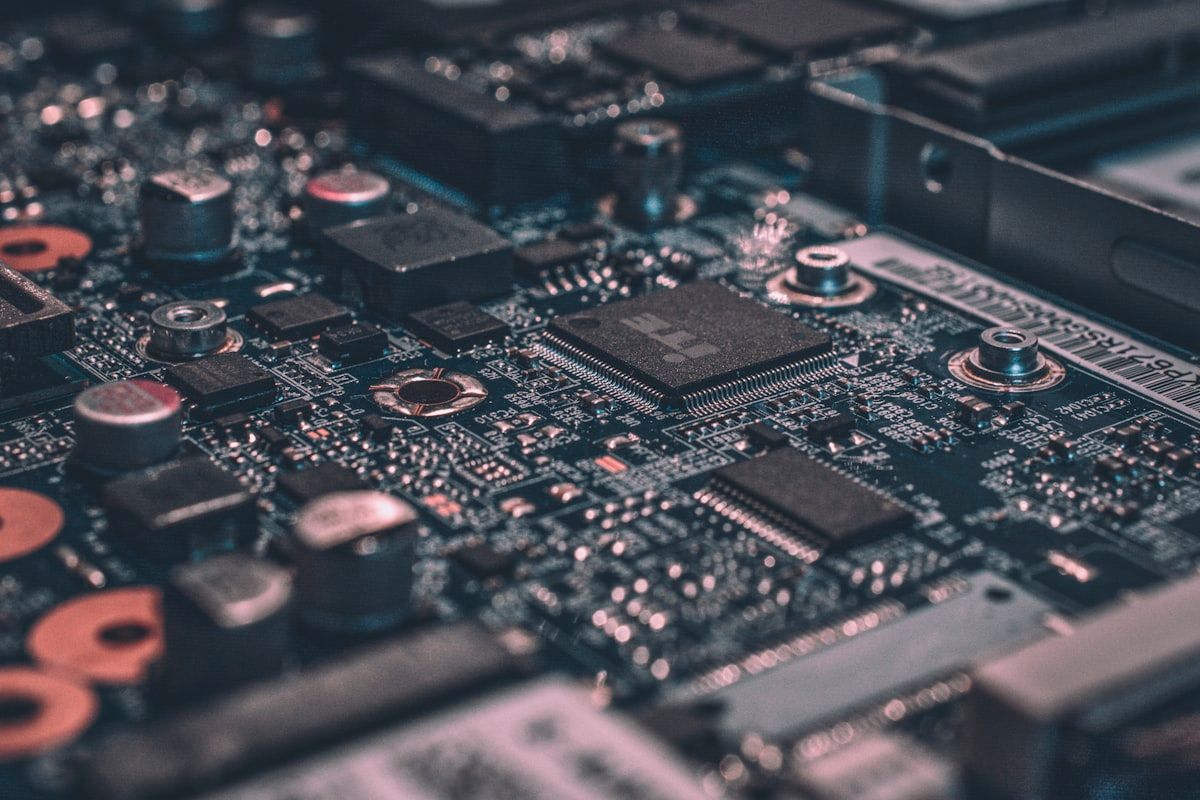

Smart manufacturing solutions with IoT integration, predictive maintenance, and digital transformation for modern factories.

They Trust in Us

We are your strategic partner. Leading companies across industries trust MOLINARI for their most critical manufacturing needs.

In Action

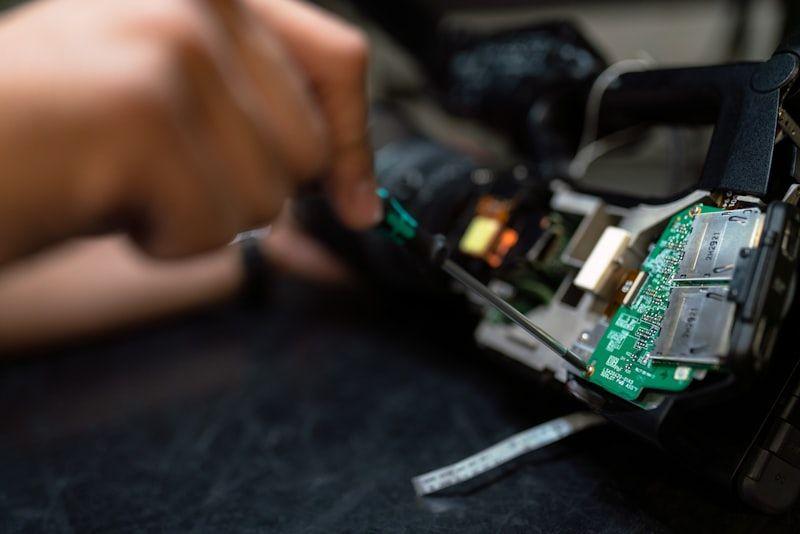

See how member companies apply advanced technologies and automation in real-world projects.

About

Over 119 years of industrial excellence in Latin America. Founders of MOLGROUP, delivering cutting-edge technologies.

Our Story

Equipment

Support

Mission

Products

Cutting-edge industrial equipment and technology designed to transform your production capabilities and maximize operational efficiency.

High-precision CNC machining centers and multi-axis lathes for complex manufacturing operations.

Complete automation systems with robotics and IoT for smart manufacturing and workflow optimization.

Advanced metrology and inspection equipment including CMM and automated testing systems.

Industrial-grade 3D printers for rapid prototyping and production with advanced materials.

Engineering Solutions in Action

Discover how our innovative engineering solutions have transformed manufacturing processes for leading international companies.

Blog

Stay informed about our latest courses, industry news, and community initiatives.

EXPOMAFE 2025 is already on our agenda, the largest industrial fair in Brazil where MOLINARI and MOLGROUP will accompany clients and represented brands.

We will be at FIMAQH 2025, the mega Argentine industrial event with our own stand where we will showcase all the technology we commercialize in the region.

Our internationally certified technicians will provide a three-day course on CNC operation and programming this year, as these jobs are key to today's production processes.

MOLGROUP Members

Discover the companies that form MOLGROUP, delivering comprehensive industrial solutions across Latin America.

Industrias

Más de 119 años de experiencia entregando soluciones a medida para los sectores industriales más exigentes de Argentina.

Soluciones de manufactura avanzada para líneas de ensamblaje automotriz, componentes de motor y producción de autopartes de precisión.

Centros de mecanizado de alta resistencia y equipos robustos diseñados para manufactura industrial a gran escala y producción de maquinaria pesada.

Soluciones especializadas en herramental y fabricación de moldes con mecanizado de alta precisión para inyección y matrices de estampado.

Equipos robustos y soluciones de mecanizado especializadas para infraestructura de petróleo y gas, tuberías y componentes del sector energético.

Mecanizado de ultra precisión y sistemas de control de calidad para componentes aeroespaciales que requieren los más altos estándares de exactitud.

Soluciones integrales de metalurgia incluyendo mecanizado CNC, tornos y automatización para fabricación metálica.

Equipos de alta resistencia y soluciones de mantenimiento diseñadas para las condiciones exigentes de operaciones mineras y procesamiento de minerales.

Soluciones de manufactura inteligente con integración IoT, mantenimiento predictivo y transformación digital para fábricas modernas.

Confían en Nosotros

Somos su socio estratégico. Empresas líderes de diversas industrias confían en MOLINARI para sus necesidades de manufactura más críticas.

En Acción

Vea cómo las empresas miembro aplican tecnologías avanzadas y automatización en proyectos del mundo real.

Nosotros

Más de 119 años de excelencia industrial en Latinoamérica. Fundadores de MOLGROUP, entregando tecnologías de vanguardia.

Nuestra Historia

Equipamiento

Soporte

Misión

Productos

Equipamiento y tecnología industrial de vanguardia diseñada para transformar sus capacidades de producción y maximizar la eficiencia operativa.

Gama completa de centros de mecanizado CNC, tornos, mandrinadoras y equipos especializados para fabricación de precisión. Desde centros de mecanizado verticales y horizontales hasta sistemas de 5 ejes y generadores de engranajes.

Soluciones completas de automatización industrial incluyendo automatización de procesos, sistemas de control y servicios especializados. Expertos en automatización proporcionando capacitación integral, precios y servicios de implementación.

Gama completa de equipos de control de calidad incluyendo máquinas de medición por coordenadas, sistemas de medición óptica, rugosímetros y herramientas de inspección dimensional.

Soluciones integrales de manufactura aditiva incluyendo impresoras 3D industriales para metales y polímeros, sistemas profesionales y soluciones integradas con Industria 4.0.

Soluciones de Ingeniería en Acción

Descubra cómo nuestras soluciones de ingeniería innovadoras han transformado los procesos de manufactura para empresas internacionales líderes.

Blog

Manténgase informado sobre nuestros últimos cursos, noticias de la industria e iniciativas comunitarias.

EXPOMAFE 2025 ya está en nuestra agenda, la mayor feria industrial de Brasil donde MOLINARI y MOLGROUP acompañarán a clientes y marcas representadas.

Estaremos en FIMAQH 2025, el mega evento industrial argentino con nuestro propio stand donde mostraremos toda la tecnología que comercializamos en la región.

EMO Hannover es una de las mayores exposiciones industriales a nivel mundial y todo MOLGROUP estará presente para ver las últimas innovaciones tecnológicas.

Miembros MOLGROUP

Descubra las empresas que forman MOLGROUP, entregando soluciones industriales integrales en toda Latinoamérica.